Master woodworking has gotten complicated with all the advanced techniques and specialized tools flying around. As someone with extensive woodworking experience, I learned everything there is to know about fine craftsmanship. Today, I will share it all with you.

Shop Notes: A Journey Into DIY Awesomeness

Shop Notes: A Journey Into DIY Awesomeness

Welcome to Shop Notes, your go-to resource for all things DIY. Whether you are new to woodworking or a seasoned craftsman, there’s always more to learn. This article covers essential tips, techniques, and tools to make your projects successful.

Essential Tools for Any Workshop

Having the right tools can make or break a project. Here are some must-have tools for any workshop:

- Table Saw: A central tool in any woodworking shop. It offers precise cuts and versatility.

- Drill Press: Provides accuracy for drilling holes, which is difficult to achieve with a handheld drill.

- Router: Perfect for adding decorative edges or creating joints.

- Jigsaw: Ideal for making curved cuts or intricate designs.

- Sander: Ensures a smooth and even finish on your projects.

- Clamps: Essential for holding pieces together while glue dries.

A well-stocked workshop also includes various hand tools like chisels, screwdrivers, and hammers.

Setting Up Your Workspace

Organization is key. A tidy workspace makes your projects efficient and enjoyable. Install pegboards to keep tools visible and within reach. Invest in sturdy workbenches to hold heavy equipment and provide ample space for assembly. Proper lighting is crucial. The right lighting reduces eye strain and helps you see fine details. Use task lights in addition to overhead lights.

Ventilation is often overlooked but crucial. Many woodworking activities generate dust and fumes. Install a good dust collection system and use fans to maintain air quality. Safety should also be a priority. Have fire extinguishers and first aid kits on hand. Make sure emergency exits are accessible and unobstructed.

Basic Techniques and Tips

Mastering basic techniques can make complex projects easier. Always measure twice and cut once. Accuracy in measurements is fundamental. Use a square to check the angles of your pieces to ensure precision. Joinery is an important skill. Learn various joints such as butt joints, dovetails, and mortise and tenon. Each has its application and strength.

When using power tools, always follow the manufacturer’s safety guidelines. Wear appropriate personal protective equipment like goggles and ear protection. Keep your blades and bits sharp. Dull tools are not only inefficient but can be dangerous. Practice makes perfect. Use scrap wood to practice new techniques before applying them to your project wood.

Choosing the Right Wood

Different projects require different types of wood. Hardwood like oak and maple is durable and great for furniture. Softwood like pine is easier to work with and good for many DIY projects. Check the moisture content of the wood. Wood with high moisture content can warp or crack as it dries. Always buy from reputable suppliers to ensure quality and consistency.

Grain direction affects the strength and appearance of the final product. Plan your cuts to follow the grain whenever possible. This not only provides structural integrity but also enhances the aesthetic appeal. Consider the finish you want to apply. Some woods take stains and paints better than others. Test on a small piece before you commit.

Project Planning and Execution

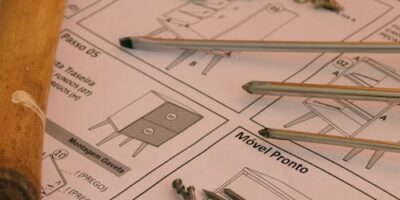

Jumping into a project without a plan can lead to wasted materials and frustration. Start with a clear blueprint. Many online resources provide free plans for various projects. Sketch your design, noting dimensions and materials needed. Make a step-by-step plan detailing each stage of the build. This helps in identifying potential issues before they arise.

Gather all your materials before starting. This can prevent interruptions during the work process. Keep a checklist to ensure nothing is missed. Follow your plan but remain flexible. Sometimes adjustments are necessary due to unforeseen circumstances like wood defects or measurement errors.

Take breaks. Working while fatigued can lead to mistakes and accidents. Stay hydrated and maintain a healthy posture to avoid strain.

Caring for Your Tools

Regular maintenance extends the life of your tools. Clean your tools after each use. Remove any dust, resin, or debris. Sharpen blades and bits regularly to ensure efficient cutting. Lubricate moving parts to prevent rust and ensure smooth operation. Store tools properly. Use cases for small tools and cover large equipment to protect from dust and moisture.

Inspect your tools periodically for any signs of wear or damage. Replace any worn-out parts immediately to prevent accidents. Keep manuals handy. They provide valuable information on tool maintenance and troubleshooting.

Common Mistakes and How to Avoid Them

Even seasoned pros make mistakes. Knowing common pitfalls can help you avoid them.

- Rushing the Job: Take your time. Precision requires patience. Hurrying can lead to errors and accidents.

- Poor Measurement: Inaccurate measurements are a leading cause of project failure. Double-check everything.

- Ignoring Grain Direction: Cutting against the grain can weaken the wood and lead to splintering.

- Skipping Safety Gear: Always use the appropriate personal protective equipment.

- Improper Tool Use: Using the wrong tool for a task can damage both the tool and the material.

DIY Project Ideas

Looking for your next project? Here are some ideas to inspire you:

- Bookshelf: A beginner-friendly project. It provides plenty of room to practice cutting, sanding, and finishing.

- Coffee Table: A more advanced project. It involves joinery and possibly using a router for decorative edges.

- Picture Frames: Great for learning precision cutting and miter joints.

- Birdhouse: Perfect for using up scrap wood. It also teaches basic assembly and finishing techniques.

- Workbench: Build the centerpiece of your workshop. Customize it with storage solutions and tool holders.

Each project helps you hone different skills. Start small and gradually take on more complex projects as your confidence grows.

Advanced Techniques to Explore

Once you’ve mastered the basics, these techniques can elevate your craftsmanship:

- Inlay: Adds a decorative touch to your projects. It involves embedding pieces of contrasting wood into a surface to create designs.

- Bending Wood: Adds curves and unique elements to your designs. This can be achieved through steam bending or kerf cutting.

- Resin Casting: Create visually stunning pieces by embedding objects or colors in resin.

- Veneering: Apply thin layers of wood to a core piece. It’s a cost-effective way to use expensive or exotic wood.

- Carving: Add intricate details and personal touches to your projects. Requires a steady hand and practice.

Continuously challenge yourself. Pushing your boundaries leads to growth and innovation in your woodworking journey.

Resources for Continuous Learning

The internet is a goldmine for learning woodworking. Websites, forums, and online courses offer a wealth of information. Join woodworking communities online. Platforms like Reddit and specialized forums provide a space to ask questions, share projects, and receive feedback.

YouTube has countless channels dedicated to woodworking tutorials. Channels like Wood Whisperer and Steve Ramsey offer high-quality content for all skill levels. Consider enrolling in online courses. Websites like Udemy and Coursera offer structured learning from professionals.

Books are also valuable resources. Titles like The Complete Manual of Woodworking by Albert Jackson and Woodworking Basics by Peter Korn are highly recommended. Don’t underestimate local resources. Community colleges and local workshops often offer classes and hands-on training.

Eco-friendly Practices in Your Workshop

Sustainability is increasingly important. Consider incorporating these eco-friendly practices:

- Choosing Sustainable Wood: Opt for woods certified by organizations like FSC to ensure responsible forestry practices.

- Using Low-VOC Finishes: Volatile Organic Compounds are harmful. Use low-VOC paints and finishes to reduce your environmental impact.

- Recycling and Reusing: Use scrap wood for smaller projects. Recycle sawdust and wood shavings.

- Energy-Efficient Tools: Choose tools that consume less energy. Look for Energy Star ratings.

- Reducing Waste: Plan your cuts to minimize waste. Use digital plans to avoid unnecessary prints.

Small changes in your workshop can contribute to a larger positive environmental impact.

The Business of Woodworking

If you have a knack for woodworking, consider turning it into a business. Start by creating a portfolio of your work. High-quality photos and detailed descriptions can make a difference. Develop an online presence. Social media platforms like Instagram and Pinterest are great places to showcase your projects. Consider creating a website or an online store on platforms like Etsy.

Network with other woodworkers and potential clients. Attend craft fairs, markets, and local events. Word of mouth is powerful. Quality and consistency are key. Build a reputation for delivering high-quality products on time.

Price your work appropriately. Factor in the cost of materials, time, and overheads. Keep an eye on market trends and adjust your pricing strategy accordingly.

Inspiring Woodworking Stories

Nothing motivates like a good success story. Consider the journey of individuals like Nick Offerman, who turned a passion for woodworking into a successful business alongside his acting career. His shop in Los Angeles is renowned for its quality craftsmanship and playful designs.

Another inspiring figure is April Wilkerson. Starting as a DIY enthusiast, she gained popularity on YouTube by documenting her projects. Today, she is a full-time content creator and offers workshops and courses.

These examples show that with passion, persistence, and a willingness to share your journey, success is within reach.

Recommended Woodworking Tools

HURRICANE 4-Piece Wood Chisel Set – $13.99

CR-V steel beveled edge blades for precision carving.

GREBSTK 4-Piece Wood Chisel Set – $13.98

Sharp bevel edge bench chisels for woodworking.

As an Amazon Associate, we earn from qualifying purchases.

Stay in the loop

Get the latest wildlife research and conservation news delivered to your inbox.